Reconditioning

Imagine your engine does not meet the expected TBOs or the components exhibit disappointing wear rates. Most fleet owners have experienced the perils of unprofessional reconditioning, overhauling single components without adequate focus on system interactions, damage from the use of leans fuels born from stronger emission standards, and unusual operating conditions – all reasons to trust the expertise of Maerkisches Werk’s Reconditioning Center.

Our cutting-edge reconditioning service means the highest quality overhauls with components manufactured in-house, and when necessary, custom solutions with modified components synchronized within the cylinder head. 40 years of experience reconditioning more than 30 types of cylinder heads and components, valve cages, liners and 2-stroke exhaust valves, built the foundation of our mission - Minimize wear to maximize TBOs in your engines.

Lifecycle Services

SUSTAINABILITY AND IMPROVED PERFORMANCE

Professional reconditioning provides the opportunity to massively improve total cost of ownership, without compromising performance. You can leverage MWH’s problem-solving expertise reconditioning single components and entire cylinder heads.

Why sustainable? Reconditioning of your components is often a viable option that can save you up to 50% compared to replacement with new components. After performing our proprietary RUBI (Rule-Based Inspection) evaluation, we will suggest a reconditioning plan. Often, that plan will include options for improving performance and durability, rendering your system and components “better than new” at a reduced price.

Repair and Enhancement Solutions

FROM OUR CUSTOMERS

"We value MWH’s willingness to share their know-how and develop solutions together."

MWH GOES BEYOND OVERHAUL AND RECONDITIONING…

MWH's knowledge base and capabilities are continuously expanding, supported by experience gained in manufacturing, systems development, product reconditioning and field activities. It is our aim to provide you with the most professional and reliable solution available and to enable the continuous use of the cylinder head and its components.

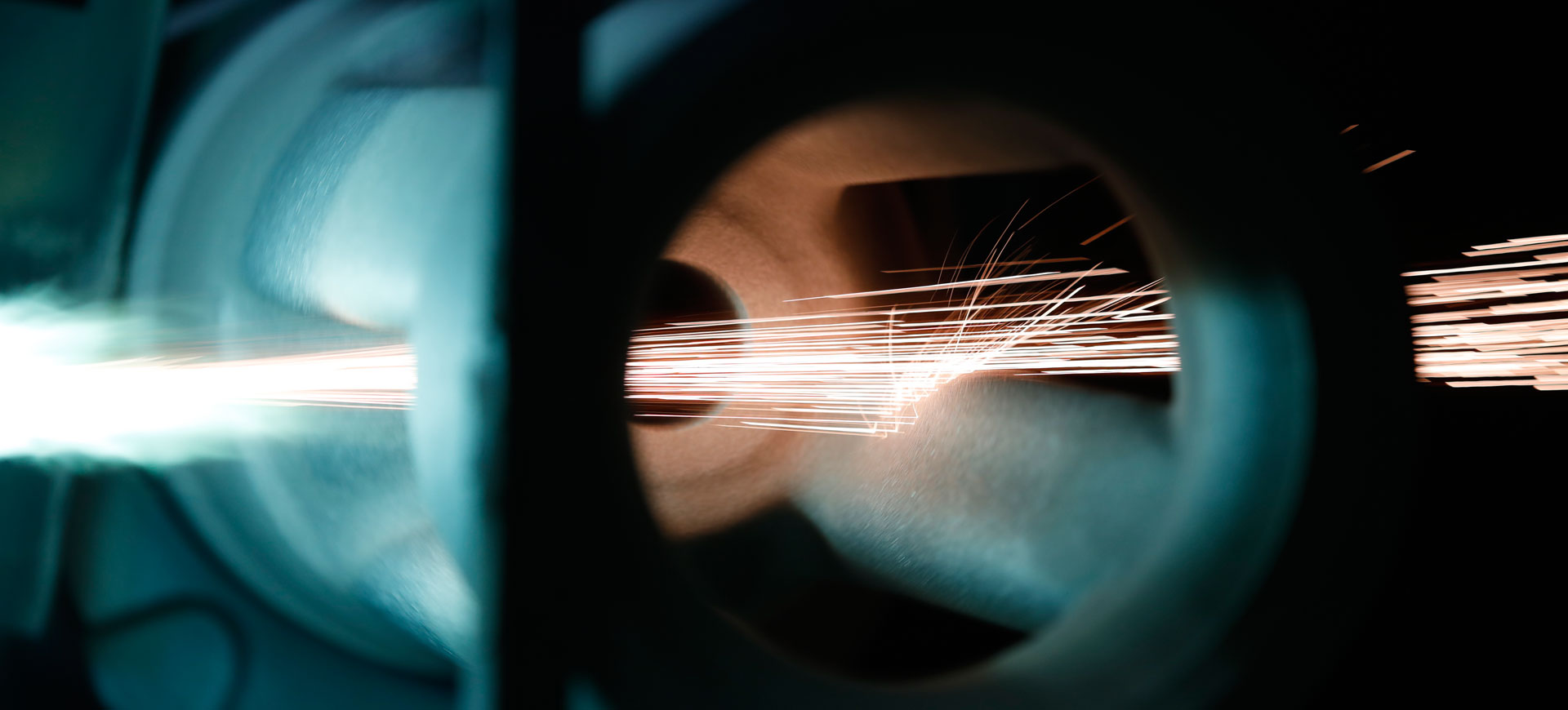

Sometimes, a standard cylinder head overhaul might no longer be possible. In this case MWH offers unique enhancement solutions. In addition to the standard wear and corrosion mechanisms which impact the running condition and lifetime of the cylinder head, the

areas between the seat ring and the seat ring pocket can be damaged by a critical cavitation process. This damage often prohibits the further use of the cylinder head. MWH developed special reconditioning procedures to allow the continuous use of the cylinder heads affected by such damage.

By transferring the cooling cycle to the insider of the seat ring, further damage to the cylinder head can be avoided, avoiding costly replacement of a valuable cylinder head.

The RUBI Advantage

OPTIMUM DIAGNOSTICS FOR OPTIMUM PERFORMANCE

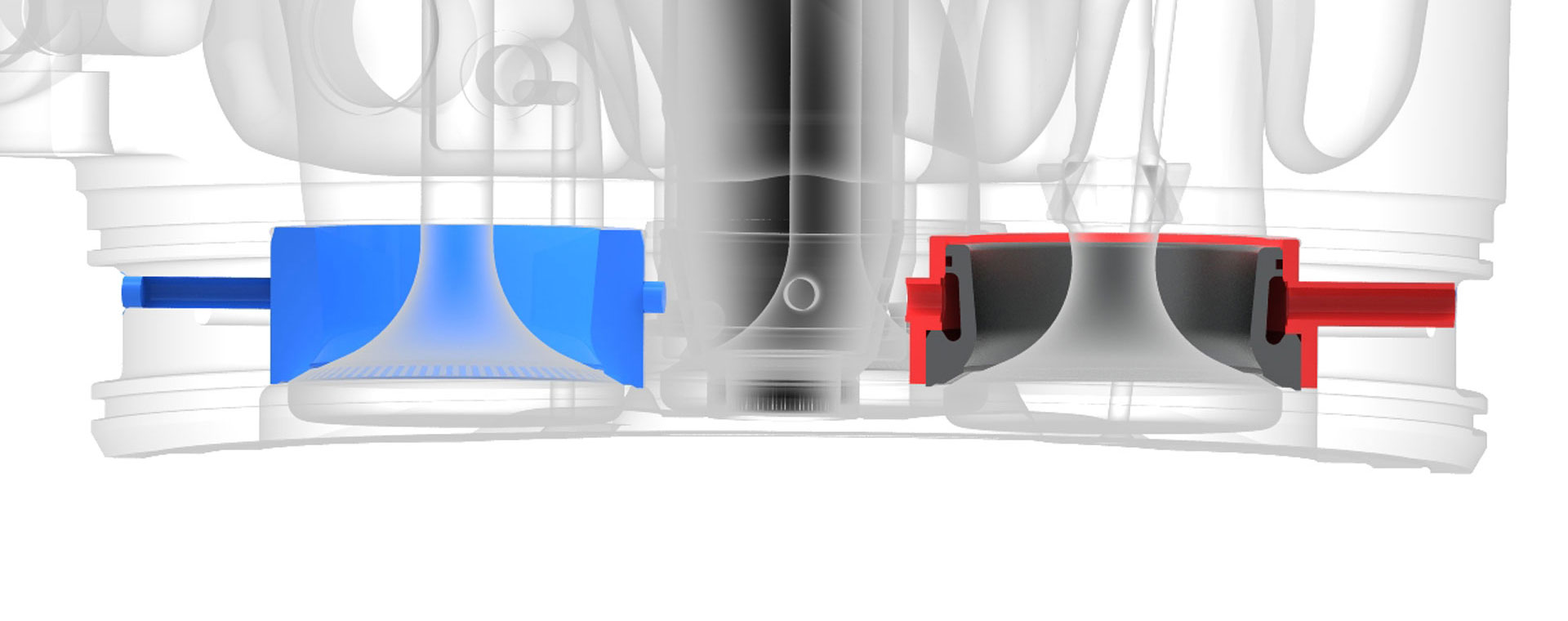

The heart of MWH’s reconditioning process is a methodical, rule-based incoming inspection process called, RUBI (Rule-Based Inspection). Decades of MWH experience lives within the RUBI framework to the benefit or customers’ valuable components. RUBI allows MWH to bring your cylinder head systems back to life.

Our standardized overhaul begins by completely dismantling each component, cleaning it and inspecting for wear and damage. MWH marks each component

with a serial number so it can be tracked. We will then know how many times the part has been overhauled, when it was overhauled, and exactly what work was carried out. It is also stamped with the MWH logo, which means we take full responsibility for the quality of the reconditioning service.

All components are reconditioned or replaced, if necessary. The system is then reassembled, tested, and a work report is issued (RUBI-OUT).

MWH Reconditioning Centers

READY TO PROVIDE ANALYSIS AND OVERHAUL SOLUTIONS

MWH operates an overhaul centre in Halver, which sends daily shipments to ports such as Hamburg and Rotterdam.

MWH Reconditioning Centers offer:

- Standardized reconditioning and modification

- Uniform quality standards

- Identical scope of service and pricing

- Installation of in-house manufactured spare parts

Processes

DESIGNED TO DELIVER EXCELLENCE

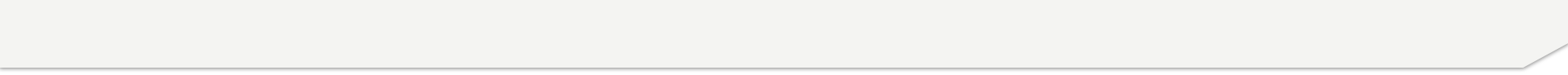

MWH reconditioning processes are uniquely designed to cover all types of wear patterns (abrasive, cold and hot gas corrosion) that affect the life of your components. We have developed procedures that allow for smooth reconditioning processes with

minimum stress impact to the complete cylinder head system. MWH’s tailor-made processes perfectly match all variations of components being reconditioned.